Categorías de productos

manguera

Articulación

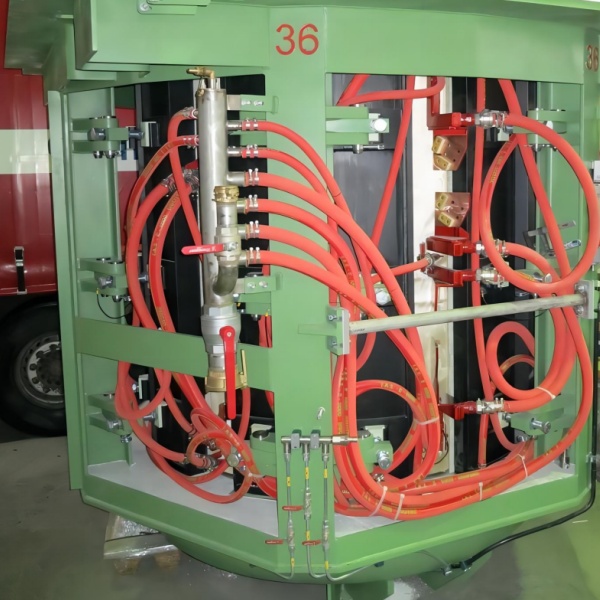

Equipos hidráulicos

Válvulas de control de fluidos

Tubos rígidos

-

Racores de manguera

- Sellos planos métricos

- Sellos esféricos métricos

- Serie de luces de cono métrico de 24°

- Serie de pesos de cono métricos de 24°

- Sello de cono métrico de 60°

- Sello de cono métrico de 74°

- Sello de cono métrico de 74 ° BSPT Rosca de tubo cónico en pulgadas

- Sello plano de rosca de tubería

- Rosca de tubo británica Sello de cono de 60°

- Junta esférica roscada de tubería

- Rosca de tubo cónico de tela NPT

- Articulaciones

- Sello de cono imperial japonés de 60°

- Sello de cono americano JIC 74°

- Sello plano ORFS de EE. UU.

- Núcleo de doble cara

- Núcleo de caucho interior y exterior de pelado de alambre de acero de seis capas

- Racores de manguera desmontables

- Racores de manguera desmontablesTipo de manguito de tubo métrico

-

Adaptadoras

- Racores de compresión DIN

- Junta tórica roscada métrica Junta plana

- Sello cónico de rosca métrica de 74°

- Junta de sello cónico roscado de 60° de tubería británica de estilo japonés

- Accesorio de sello de cono de 60 ° con rosca de tubería británica

- Accesorios BSPT roscados de tubería cónica en pulgadas

- Accesorios NPT roscados de tubería cónica americana

- Accesorios abocinados de rosca cónica de 74° de EE. UU.

- Accesorios ORFS de junta tórica roscada de EE. UU.

- Articulaciones de navegación

- Uniones de bridas

- Accesorios de compresión gemelos

- Acoplamientos rápidos

- Articulaciones giratorias

-

Conectores industriales

- Conectores TW

- Herrajes franceses

- Herrajes de material compuesto

- Herrajes americanos

- Acoplamientos rápidos estándar alemanes

- Acoplamientos rápidos estándar alemanes

- Conectores higiénicos para alimentos

- Juntas de barro

- Conectores de aire Euro

- Conectores de aire de estilo americano

- Conectores de vapor de estilo americano

- Herrajes alemanes (Geka)

- Acoplamientos rápidos en seco

- Accesorios de prueba de presión

- Accesorios de montaje

- Máquina prensadora de mangueras

- Máquina de preinstalación de férulas

- Máquina de extrusión de extremos de tubos

- Máquina cortadora de tubos hidráulica

- Arandela de manguera

- Banco de pruebas de presión

- Molde de máquina prensadora

- Máquina peladora de mangueras

- Máquina peladora de manguerasDobladora CNC tridimensional

- Máquina preinstalada con conector

- Industria

-

solución

- Cuatrimotos

- Equipos de CVD/grabado

- Horno eléctrico de media frecuencia

- Carro de brazo de cucharón aislado

- Manguera del amortiguador

- Solución de sistema de encolado para vehículos completos

- Soluciones de componentes de fluidos para equipos médicos

- Soluciones de conexión de fluidos para ingeniería marina

-

Conocimiento

- Características de la tubería de vapor

- Cómo elegir un tubo sin carbono

- Aplicación de tubos aislados en hornos de arco sumergido

- Rompiente

- Características del accesorio de doble tubo

- Características del conector de navegación HB4-4FA-2002

- La diferencia entre la manguera de alambre de acero 4SP y 4SH

- Acoplamientos rápidos de tapón ciego refrigerados por líquido

- Conjunto de tubería de acero de ultra alta pureza

- Manguera de teflón (PTFE) del dispensador

- Instrucciones de instalación del montaje de la manguera

- Núcleo de brida SAE

- Conjunto de cilindros de acero para sistema de extinción de CO2

- Compresor de pistón seco accionado hidráulicamente

- Introducción al estándar de mangueras hidráulicas SAE J517

- Gabinete de alimentación de frecuencia intermedia de resonancia en serie sin tubo de carbono

- Sobre nosotros

- Historia de la marca